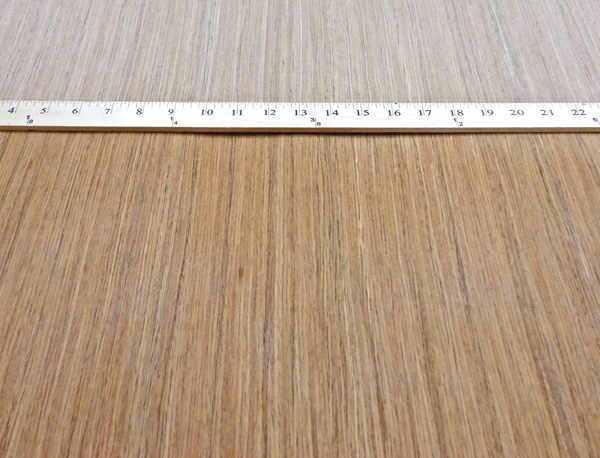

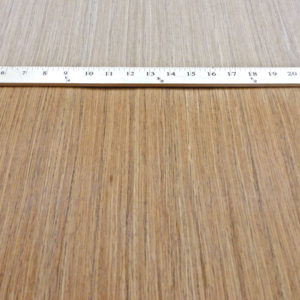

Teak Quarter Cut composite # EFW wood veneer sheet with several options of size and backing. Composite wood veneers are made of real wood in a process that utilizes cutting and dyes to produce consistent, clean, defect free designs. Each sheet is carefully inspected for quality and based on our experience in the industry since 1995. This product will look very close to the pictures, which is one of the attractive features of composite wood veneers also often called “recon” short for reconstituted engineered wood. This wood is often used as a substitute for natural Teak because of the cost. It will accept most finishes.

Size options:

Many sizes with varying grain directions from 1′ x 1′ all the way to 5′ x 10′. Grain direction is always the second number listed. See options on drop down size menu.

Backer options:

Paper backer = 1/40” thickness and will be a Beige color or a Brown color. Whichever matches the wood best. Paper backer flexibility will generally wrap around a soda can as example. The paper remains on the product and holds it together at the seams and during lamination to a substrate.

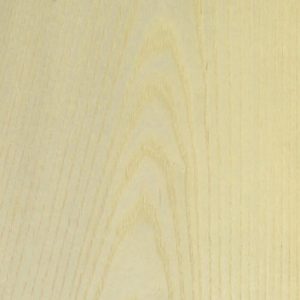

Wood backer = 1/25” thickness and currently is an Ash composite color, but some items may have Okuome Mahogany. The grain on the backing sheet runs the opposite direction of the face wood veneer in order to minimize the pull of the grain from the front side. Wood backer is sometimes preferred because it will absorb contact cement better than paper backer and it is thicker. Wood backer flexibility will generally wrap around a 2 liter soda bottle as example.

PSA backer = 1/40” thickness. This is peel and stick pressure sensitive adhesive made by 3M. PSA products have a paper backer on them with the adhesive added to that backer and protected by a liner film that peels off when ready to apply to a substrate. Wood backed products can also have PSA added. PSA size limitation is 4’ wide and 12’ long since the PSA comes from 4’ wide longer rolls. 3M offers a high quality adhesive that works well when applied to a proper surface. This product eliminates the need for brushes, contact cement and the chemical odor that comes with contact cement.

Application:

Paper and wood backed products are generally applied with contact cement since that process doesn’t require pressure. There are many other methods including white and yellow wood glues, but these require pressure as with a press, clamping or a vacuum bag. Application instructions can be found on our website for the PSA and contact methods. There are also plenty of video tutorials available online with slightly differing methods. A simple search using the terms “how to apply wood veneer” will produce many results. Here are the application instructions for each: Application instructions for all backed wood veneer sheets

Shipping lead times:

Generally, sizes under 4’ x 12’ will ship within 1-2 days with some exceptions. 5’ wide items usually will require a lead time of 1-2 weeks. Some sizes may be available, but not show pricing. In this case, the site will offer a contact for more information. If the shipping time is crucial, please inquire. Especially if you need expedited shipping services. All backed veneer products will ship rolled in long narrow boxes that are proven effective to arrive without damage. If a package arrives damaged, please take pictures of the box and the damaged product and advise.

Pictures:

A great deal of time, effort and editing goes into photographs of our products. Most pictures are “representative” of what the product will actually look like except with “composite” reconstituted engineered woods which will always have the name composite in the item description and usually a code number or letters. These products will look extremely close to what is received, which is one of many things that makes them attractive. But natural grown wood veneer products will vary in color and grain and some reasonableness expected. The veneer photo gallery and the customer project section will also provide additional pictures of many of the woods. Some photos may show wet or finished wood veneer and customer projects.

| Weight | N/A |

|---|---|

| Dimensions | N/A |

| Size | 12" x 12", 24" x 24", 24" x 48", 48" x 24", 12" x 96", 24" x 96", 36" x 96", 48" x 48", 48" x 96", 96" x 48", 48" x 120", 48" x 144", 60" x 96", 60" x 120", 60" x 144" |

| Backer Option | Paper, Wood, PSA |

Related products

Wood Veneer Sheets

Wood Veneer Sheets

Wood Veneer Sheets

Wood Veneer Sheets

Wood Veneer Sheets

Wood Veneer Sheets

Wood Veneer Sheets

Wood Veneer Sheets